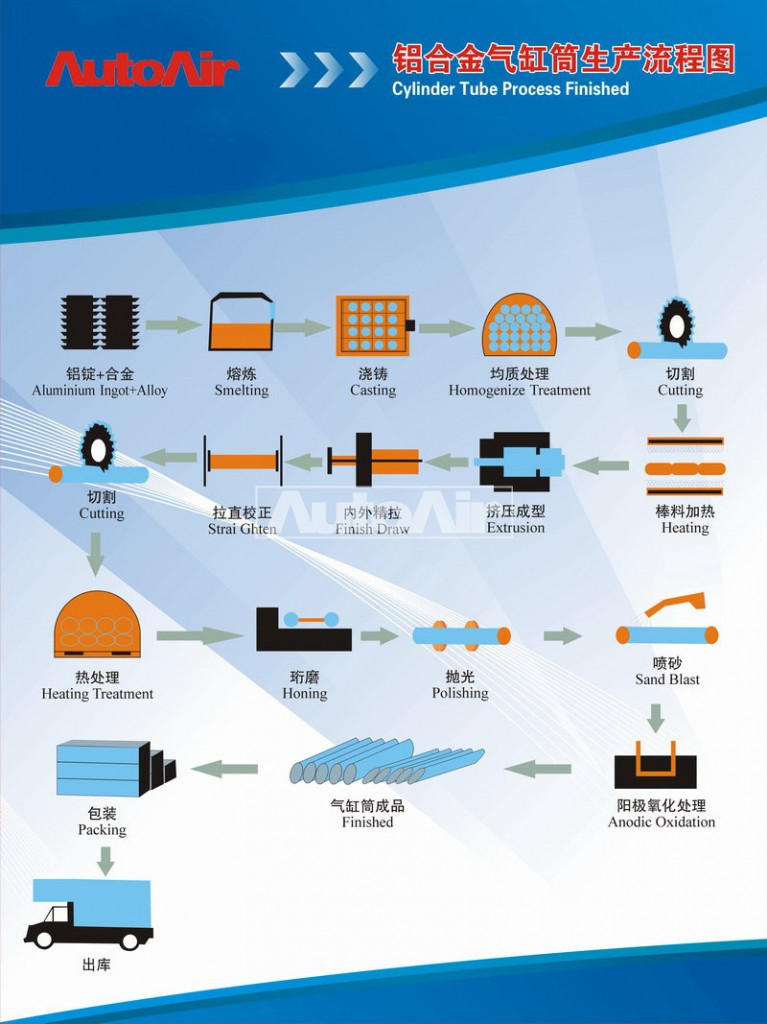

Habka Wax Soo Saarka ee Tuubada Silinder Pneumatic

Aqoon-is-weydaarsiga alaabta ceeriin

Aqoon-is-weydaarsiga alaabta ceeriin

Workshop Extrusion

Workshop Extrusion

Dhamaystir aqoon-is-weydaarsiga Sawir-qaadista

Dhamaystir aqoon-is-weydaarsiga Sawir-qaadista

Honing Workshop

Honing Workshop

Aqoon-is-weydaarsiga Polishing

Aqoon-is-weydaarsiga Polishing

Aqoon-is-weydaarsiga Qarax Ciidda

Aqoon-is-weydaarsiga Qarax Ciidda

Aqoon isweydaarsiga Oxidation Anodic

Aqoon isweydaarsiga Oxidation Anodic

Xirmooyinka tuubada dhululubada pneumatic

Xirmooyinka tuubada dhululubada pneumatic

Aqoon-is-weydaarsi agab diyaarsan

Aqoon-is-weydaarsi agab diyaarsan

Ugu horreyntii, ka dib markii la helo sawirada macaamiisha ee la habeeyey ama macaamiishu waxay qaataan sawiradayada caadiga ah, waxaanu iibsan doonaa alaabta ceeriin ee furitaanka caaryada.

Tallaabada 1:Muuqaalka aluminium ee la sii daayay sida ku cad sawirka caaryada

2 qaybood oo ah mashiinnada extrusion profile aluminium culeys-culus

Tallaabada 2:dhame barbaradka

Tallaabada 3:toosi

Tallaabada 4:Goynta

Tallaabada 5:Daaweynta kululaynta

Tallaabada 6:Sharafta

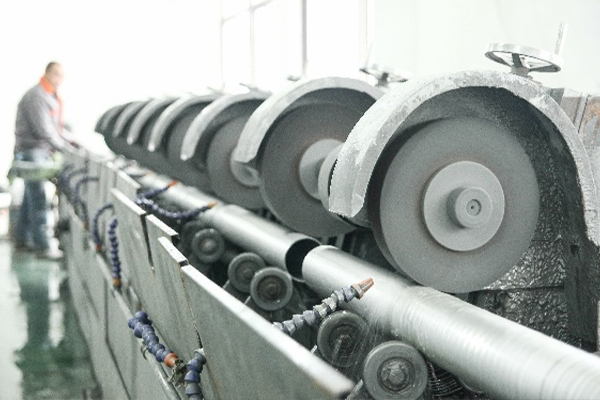

12 qaybood oo ah mashiinnada tuubada dhululubo ee pneumatic

FAQ:

Q1: Waa maxay honing?

J: Dhamaystirka habaynta dusha dhamaystirka leh dhagaxa whetstone (sidoo kale loo yaqaan ul honing) ee ku dhex jira madaxa honing.Sidoo kale loo yaqaan caajis.Waxay inta badan ka shaqeysaa godadka cylindrical kala duwan oo leh dhexroor 5 ilaa 500 mm ama xitaa ka weyn, iyo saamiga qoto dheer ee daloolka dhexroorka daloolka wuxuu gaari karaa 10 ama ka badan.Xaalado gaar ah, waxay sidoo kale farsameyn kartaa diyaaradaha, dusha wareegyada dibadda, sagxadaha wareegsan, sagxadaha iliga, iwm. dhererka daloolka.Marka daloolku sifeeyo, wuu rogrogaa oo hore iyo gadaal ayuu u dhaqaaqaa.Isla mar ahaantaana, waxay si siman ugu fidaysaa guga ama kantaroolka hydraulic ee madaxa honing.Sidaa darteed, meesha xidhiidhka leh ee dusha sare ee daloolka ayaa ka weyn, waxtarka wax-qabadka ayaa sarreeya.Saxnaanta cabbirka godka ka dib marka la isku daro waa IT7 ~ 4, iyo qallafsanaanta dusha sare waxay gaari kartaa Ra0.32 ~ 0.04 microns.Cabbirka gunnada honing waxay kuxirantahay dhexroorka daloolka iyo walxaha workpiece, guud ahaan 0.02 ~ 0.15 mm qaybaha birta ah iyo 0.01 ~ 0.05 mm qaybaha birta.Xawaaraha wareega ee madaxa honing guud ahaan waa 100 ~ 200 rpm, iyo xawaaraha dhaqdhaqaaqa isdhaafsiga guud ahaan waa 15 ~ 20 m/min.Si meesha looga saaro jajabyada wax lagu gooyo iyo walxaha xaaqaya, wanaaji qallafsanaanta dusha sare iyo in la yareeyo heerkulka aagga goynta, xaddi badan oo dareere ah oo goynta ah, sida kerosene ama qadar yar oo saliid bir ah, ayaa badanaa la isticmaalaa inta lagu jiro hawlgalka, iyo Mararka qaarkood emulsion cadaadis daran ayaa sidoo kale la isticmaalaa.

Tallaabada 7:shaandhaynta

2 qaybood oo ah mashiinnada nadiifinta dusha sare

Tallaabada 8:Bacaad qarax

2 qaybood oo ah mishiinada ciidda qarxinta

FAQ

Q1: Waa maxay qaraxa ciidda?

A: Habka loo isticmaalo saamaynta socodka ciid-xawaaraha sare leh si loo nadiifiyo oo loo qallajiyo dusha sare ee substrate-ka.Hawada cufan waxaa loo isticmaalaa sidii awood si loo sameeyo laydhka jet-xawaaraha sare leh si loo buufiyo walxaha buufinta (macdanta naxaasta, ciid quartz, ciid emery, ciid bir ah, ciid Hainan) xawaare sare ilaa dusha sare ee workpiece si loo daweeyo, si muuqaalka ama qaabka dusha sare ee dusha sare ee workpiece waa la bedelay , Sababtoo ah saameynta iyo goynta ficilka xoqida dusha sare ee shaqada, dusha sare ee shaqada ayaa heli kara heer gaar ah oo nadiif ah iyo qallafsanaan kala duwan, si sifooyinka farsamada ee dusha workpiece ah ayaa la wanaajiyey, sidaas darteed hagaajinta caabbinta daalka ee workpiece, iyo kordhinta ay iyo daahan The adhesion u dhexeeya lakabyada kordhiyaa adkeysiga filimka daahan, iyo sidoo kale waa ku haboon si ay u siman iyo decoration ee daahan.

Tallaabada 9:Anodizing

2 qaybood oo ah khadadka daawaynta anodizing

FAQ:

Q1: Waa maxay anodizing?

J: oksaydheynta anodic, oksaydhka korantada ee biraha ama alloys-ka.Aluminium iyo alloyskeeda waxay sameeyaan lakabka filimka oxide ee alaabooyinka aluminium (anode) ee hoos yimaada ficilka hadda la dabaqay ee hoos yimaada korantada u dhiganta iyo xaaladaha habka gaarka ah.Haddii anodizing aan la cayimin, waxa badanaa loola jeedaa sulfuric acid anodizing.

Si looga adkaado cilladaha qallafsanaanta aluminiumka aluminiumka, xirashada caabbinta iyo dhinacyo kale, ballaarinta baaxadda codsiga, iyo kordhinta nolosha adeegga, tignoolajiyada daaweynta dusha ayaa noqotay qayb aan lagama maarmaanka u ah isticmaalka daawaha aluminiumka, iyo tignoolajiyada anodizing hadda waa kan ugu isticmaalka badan uguna guulaysta.

Tallaabada 10:Tuubooyinka dhululubada aluminium ee dhammaatay

Tallaabada 11:Xirmooyinka tuubooyinka dhululubada aluminium