S45C Hard Chrome Plated Piston Usha Loogu Talagalay Dabaqadaha Pneumatic

Usha piston ee dhululubo ee pneumatic waxaa sidoo kale loo yaqaannaa usha chrome-plated.Waa ul dusha sare leh oo lagu daweeyo shiidi gaar ah iyo dahaadh adag oo chrome ah.Waxaa si weyn loogu isticmaalaa dhululubo kala duwan, dhululubo haydarooliga, baakadaha, alwaax, miiqan, daabacaadda iyo mashiinada dheeh, qaybo dhinta-kabka iyo qalabka kale ee gudbinta si toos ah sababta oo ah ay adag tahay, taas oo kordhin kara nolosha adeegga mashiinada saxda ah iyo qalabka caadiga ah.

Waxaan qaadanay saxan qabow oo la sawiray, hurin iyo turxaan bixin si aan u soo saarno usha bisinka ee dhululubada sambabada, bartilmaameed kasta oo farsamo waxa uu buuxiyaa heerka qaranka.

Faahfaahinta Faahfaahin

Qalabka: CK45 (GB/T699-1999)

Qeexitaanka makaanikada:

Xoog xajin (Mpa):≥600N/mm2

0,2 Soo saarista Cadaadiska(Mpa):≥355N/mm2

Kordhinta: min.16%

Dhumucdiisuna waxay dahaaran tahay Chrome: φ<20mm≥15μm, ka φ20mm :20μm

Qalafsanaan: Ra | 0.2

Lakabka Adag ee Chrome:850HV-1050HV

Dulqaadka dhexroorka: f7,f8

Toosan: <0.1um/1000mm

Ovality: 1/2 dulqaad dhexroor

Qiimaynta Corroseston Test:ISO 10289:1999,IDT

Dhexroorka dibadda:3-120mm (GCr15) 3-40m(SUS440C)

Xaaladda dhalmada: Caadi, Soo-galin Harden, Q+T

Shaxda ka kooban kiimikada

| KA MID AH kiimiko (%) | |||||||

| Qalab | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <=0.22 | <= 1.6 | <=0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Dhexroorka | Miisaanka | Dulqaad | Dulqaad | Dulqaad |

| mm | Kg/m | f7 (μm) | f8 (μm) | h6 (μm) |

| 6 | 0.22 | -10--22 | -10--28 | 0--9 |

| 8 | 0.39 | -13--28 | -13--35 | 0--9 |

| 10 | 0.62 | -13--28 | -13--35 | 0--11 |

| 12 | 0.89 | -16--34 | -16--43 | 0--11 |

| 16 | 1.58 | -16--34 | -16--43 | 0--11 |

| 18 | 2.00 | -16--34 | -16--43 | 0--13 |

| 20 | 2.47 | -20--41 | -20--53 | 0--13 |

| 22 | 2.99 | -20--41 | -20--53 | 0--13 |

| 25 | 3.86 | -20--41 | -20--53 | 0--13 |

| 28 | 4.84 | -20--41 | -20--53 | 0--13 |

| 30 | 5.55 | -20--41 | -20--53 | 0--16 |

| 32 | 6.32 | -25--50 | -25--64 | 0--16 |

| 36 | 8.00 | -25--50 | -25--64 | 0--16 |

| 38 | 8.91 | -25--50 | -25--64 | 0--16 |

| 40 | 9.87 | -25--50 | -25--64 | 0--16 |

| 45 | 12.49 | -25--50 | -25--64 | 0--16 |

| 50 | 14.22 | -25--50 | -25--64 | 0--19 |

| 55 | 15.43 | -30--60 | -30--76 | 0--19 |

| 60 | 18.66 | -30--60 | -30--76 | 0--19 |

| 65 | 26.07 | -30--60 | -30--76 | 0--19 |

| 70 | 30.23 | -30--60 | -30--76 | 0--19 |

| 75 | 34.71 | -30--60 | -30--76 | 0--19 |

| 80 | 39.49 | -30--60 | -30--76 | 0--22 |

| 85 | 44.58 | -36--71 | -36--90 | 0--22 |

| 90 | 49.98 | -36--71 | -36--90 | 0--22 |

| 95 | 55.68 | -36--71 | -36--90 | 0--22 |

| 100 | 61.70 | -36--71 | -36--90 | 0--22 |

Waa maxay heerarka dulqaadka f7 iyo f8:

Baaxadda dulqaadka ee f8 way ka weyn tahay kan f7, rakibidduna waxay ku xidhan tahay heerka aaga dulqaadka dalool ee u dhigma.Tusaale ahaan, marka cabbirka aasaasiga ah uu yahay 10-18, f8 (-0.016,-0.034), f7 (-0.016,-0.027), leexinta labada dulqaad waa isku mid, kala duwanaanshaha f7 waa yar yahay, iyo nadiifinta kala duwanaanshaha ku habboon rakibaadda ayaa ka yar.

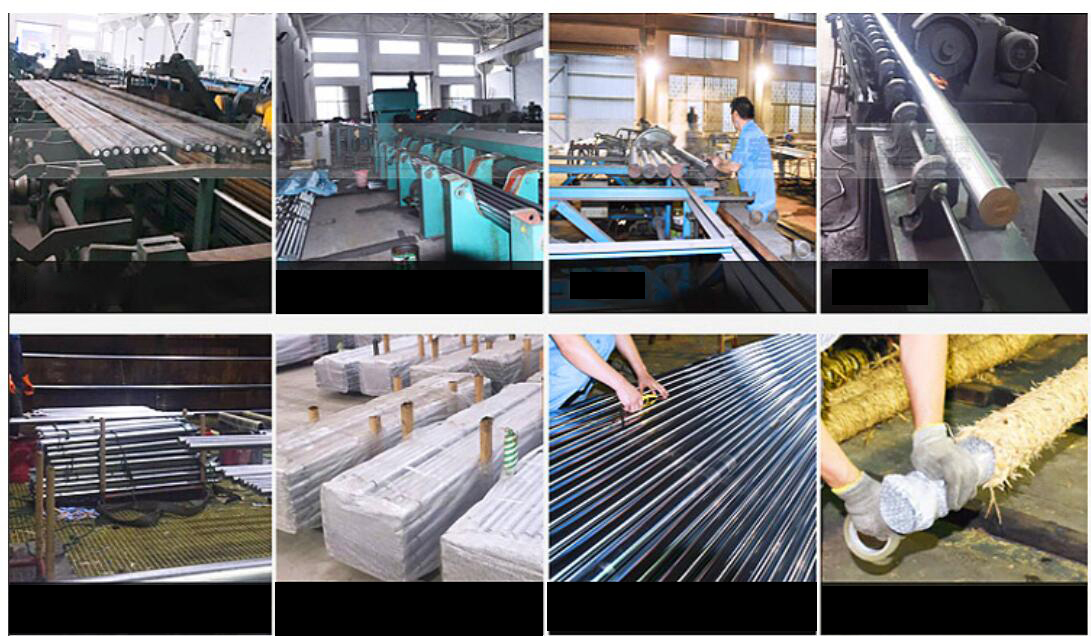

Socodka wax soo saarka

1 Tallaabo: Diiritaanka/ Qabow oo La sawiray:

Sawirka qabow waa tignoolajiyada farsamaynta usha piston cylinder ee pneumatic.Dhululubada pneumatic-ka adag ee usha dahaadhka ah ee chrome, sawir qabow waxa loola jeedaa sawirida xaalada heerkulka caadiga ah si loo gaadho qaab gaar ah iyo sifooyin farsamo oo gaar ah.Marka la barbar dhigo samaynta kulul, alaabada qabow ee la sawiray waxay leeyihiin faa'iidooyinka saxnaanta cabbirka sare iyo dhammaystirka dusha sare.

2 Talaabo: Toosin

Tallaabadan waxaan hubin karnaa in usha adag ee chrome-ka lagu dhejiyay ay toosan tahay.Aad bay muhiim u tahay, marka la rakibo gudaha dhululubada pneumatic.Toosanaanta caadiga ah waa 0.2mm/m.

3 Talaabada: Sharafta

Processing Honing waa hab wax ku ool ah ka baaraandegi in awood usha pneumatic cylinderen usha si ay u gaaraan sax sare, tayada dusha sare iyo nolosha dheer.Waxay si wax ku ool ah u wanaajin kartaa saxnaanta cabbirka, qaabeynta saxnaanta waxayna yareyn kartaa qiimaha Ra, laakiin ma hagaajin karto booska daloolka iyo meelaha kale.

Talaabada 4aad: Usha birta ah oo saliimaysa

Daalidda waxaa loola jeedaa isticmaalka farsamooyinka, kiimikooyinka ama saameynta korantada si loo yareeyo qallafsanaanta dusha sare ee usha piston cylinder ee pneumatic si loo helo dusha dhalaalaya oo siman.Waa isticmaalka aaladaha daalidda iyo walxaha xoqan ama warbaahinta kale ee polishing si wax looga beddelo dusha sare ee usha piston cylinder ee pneumatic

Talaabada 5: Chrome Plating

Dahaarka chrome waxa loola jeedaa falka lagu dhejiyay chromium sida dahaarka sambabada sambabada sambabada ee pneumatic adag.

Lakabka chromium-plated wuxuu leeyahay qallafsanaan aad u sarreeya, qallafsanaantiisuna waxay ku kala duwanaan kartaa tiro balaadhan oo ah 400-1200HV iyadoo loo eegayo habka xalinta dajinta iyo xaaladaha habka.Lakabka chrome-plated wuxuu leeyahay iska caabin kulayl oo wanaagsan.Marka lagu kululeeyo meel ka hooseysa 500 ℃, ma jiro isbedel muuqda oo dhalaalid iyo adayg.Heerkulku wuxuu bilaabi doonaa inuu oxidize oo midab beddelo marka heerkulku ka sarreeyo 500 ℃, iyo engegnaanta ayaa hoos u dhici doonta marka ay ka sarreyso 700 ℃.Iskuxidhka iskuxiran ee lakabka chrome waa yar yahay, gaar ahaan iskudhafyada qalalan ee qalalan, kaas oo ah kan ugu hooseeya dhammaan biraha.Sidaa darteed, lakabka-chrome-plated wuxuu leeyahay caabbinta xirashada wanaagsan.

Lakabka lakabka chromium wuxuu leeyahay degganaansho kiimiko oo wanaagsan.Wax saameyn ah kuma laha alkali, sulfide, nitric acid iyo inta badan asiidhyada organic, laakiin waxaa lagu milmi karaa pneumatic acid (sida pneumatic acid) iyo sulfuric acid kulul.Qiyaasta iftiinka muuqda, milicsiga chromium waa qiyaastii 65%, taas oo u dhaxaysa qalin (88%) iyo nikkel (55%).Sababtoo ah chromium ma beddelo midabka, waxay sii wadi kartaa muuqaalkeeda wakhti dheer waxayna ka fiican tahay qalin iyo nikkel.

Talaabada 6: Usha Chrome-ka leh ee dahaadhka ah oo dhalaalaysa daminta kadib

Electroplating iyo polishing: waa laba hab oo kala duwan oo loogu talagalay daawaynta dusha sare ee biraha iyo walxaha kale.Midda hore waa daaweynta kiimikaad, tan dambena waa daawaynta farsamada.

Electroplating: Habka loo isticmaalo electrolysis si loogu dhejiyo lakabka filimka birta ee dusha birta ama walxo kale.Waxay ka hortagi kartaa daxalka, hagaajinta caabbinta xirashada, korantada korantada, milicsiga iyo kor u qaadida bilicda.

Daalid: Isticmaal agabka dhalaalidda dabacsan iyo walxaha xoqan ama warbaahinta kale si aad wax uga beddesho dusha sare ee shaqada.Daliishantu ma hagaajin karto saxnaanta cabbirka ama saxnaanta joometeriga ee qaybta shaqada, laakiin waxay ujeeddadeedu tahay in la helo oog siman ama dhalaal muraayad ah.

Talaabada 7: Tijaabinta Tayada Usha Chrome ka samaysan

Ulaha bistoonka ee lagu sameeyay habka korantada iyo nadiifinta waxaa badanaa la socda cilladaha dahaarka sida godadka chrome iyo godad.Baaxadda iyo tirada cilladahan waxay si toos ah u saameeyaan waxqabadka usha piston.Si loo yareeyo saameynta cilladahan ee usha piston, dhinaca kale, iyada oo la hagaajinayo tayada alaabta ceeriin, hagaajinta tignoolajiyada farsamaynta, iyo yaraynta dhacdooyinka cilladaha;Dhanka kale, waxaa lagama maarmaan ah in si sax ah loo ogaado cilladaha dhejiska ka dib habka polishing si looga fogaado alaabooyinka aan u qalmin inay ka baxaan warshadda.Injineerada Autoair waxay xaqiijiyaan ogaanshaha cilada tooska ah iyagoo kaashanaya aqoonta sayniska sawirka

Talaabada 8: Xiritaanka

FAQ:

Q1: Waa maxay usha piston dhululubo pneumatic ah?

A: Usha piston waa qayb aasaasi ah oo muhiim ah oo ka mid ah dhululubo kasta oo hawo-mareen ama pneumatic ah.Usha bistoonka sida caadiga ah waa mashiin sax ah oo dhererkiisu yahay chrome adag oo lagu dhejiyay birta qabow ee dhammaatay kaas oo u gudbiya xoogga uu abuuray bistoonku qaybta mashiinka qabanaysa shaqada.

Q2: Waa maxay mabda'a usha piston cylinder pneumatic?

A: Piston dhululubada pneumatic ee dhululubo wuxuu sitaa riixa ama jiidashada xoogga ka dhashay cadaadiska hawada, oo si toos ah u dhaqmo on usha pneumatic cylinderen usha piston ah, ka dibna usha pneumatic cylinderen usha waxay ku xiran tahay workpiece load si uu u dhaqaaqo. gadaal iyo gadaal.

Q3: Waa maxay alaabta ceeriin ee ushaada pneumatic cylinder cylinder

A: Caadi ahaan, usha piston cylinder pneumatic ee dhululubada pneumatic waxay dooran doontaa 45 # birta sida alaabta ceeriin.Haddii dhululubada la soo saaray loo baahan yahay in lagu isticmaalo deegaan gaar ah, 304 birta aan la taaban karin ayaa sidoo kale la isticmaali karaa

Q4: Maxaad u doorataa 45 # birta alaab ceeriin ah

A: 45# birta waa bir dhismeed kaarboon oo tayadeedu sareyso lehna adkeysi yar iyo goyn fudud.Ka dib marka la demiyo, engegnaantiisa oogada waxay gaari kartaa 45-52HRC.Waxayna sidoo kale yeelan kartaa wax qabad wanaagsan oo goyn ah iyo xoog sare, adkaansho iyo qalabyo farsamo oo dhamaystiran, sidaas darteed waa mid ka mid ah qalabka sida caadiga ah loo isticmaalo qaybaha shafka.

Q5: Waa maxay habka farsamaynta ee ushaada pneumatic dhululubada?

J: Si loo helo tayada makiinado xasiloon, toosinta gacanta ee usha piston lama ogola ka dib marka mishiinku bilaabo.Sidaa darteed, habka toosinta waa in la sameeyaa ka hor inta aan la samayn mashiinka.Sababtoo ah qallafsanaanta liidata ee qalabka shaqada, leexashada qallafsan iyo rogid fiican waa in la fuliyaa inta lagu jiro habka farsamaynta si loo hagaajiyo saxnaanta mashiinka.Habka shaqada ee usha piston ayaa isweydaarsanaysa dhaqdhaqaaqa toosan.Si loo hagaajiyo nolosha adeegga ee usha piston, dusha sare waa in lagu dhejiyaa chrome-plated si loo hagaajiyo adkaanta dusha sare iyo xirashada caabbinta.Ka dib dahaadhidda chrome, daawaynta sifaynta ayaa loo baahan yahay si loo helo qallafsanaanta dusha sare, la dhimo khilaafka, oo loo hagaajiyo waxqabadka xidhidhiyaha.Maaddaama habka polishing uusan wax saameyn ah ku yeelan dhexroorka dibadda ee usha piston, workpiece wuxuu u baahan yahay si loo gaaro qallafsanaanta dusha sare ka hor inta aan la dhejin chrome.Sidaa darteed, waxaa lagama maarmaan ah in lagu daro habka qashin-qubka ka hor inta aan la marin habka chrome-ka (sida saxda ah waxay sidoo kale hagaajin kartaa adhesion dusha sare ee chromium. ).Iyada oo ku saleysan falanqaynta sare, hababka hab-socodka ee macquulka ah ee usha piston waa: toosinta-rogid-qallafsan-rogid-fiican-shiidid-chrome plating-polishing.

Q6: Waa maxay polishing usha piston cylinder pneumatic

A: Inta lagu jiro habka rogid, daloolka dhexe ee ka ciyaara doorka meelaynta wuxuu muujin doonaa heer go'an oo xiran.Si loo hubiyo mabda'a midaysan ee jaangooyooyinka, daloolka dhexe waa in la gooyaa ka hor inta aan la shiidi si loo hubiyo tayada farsamaynta.Marka wax la shiidi karo, tijaabinta tijaabinta waa in lagu fuliyaa goobada dibadda ee u dhow dhamaadka marka hore, iyo shiidida usha piston waxaa la samayn karaa oo keliya marka xaalada runout buuxiso shuruudaha processing.Marka lagu daro hagaajinta saxnaanta cabbirka, geeddi-socodka qashin-qubka wuxuu kaloo u baahan yahay inuu helo qallafsanaan sare oo dusha mashiinka ah si loo hagaajiyo xiriirka ions chromium inta lagu jiro habka korantada.Si loo hubiyo in dhumucda lakabka lakabka chromium ee usha piston ee ugu dambeysa ay tahay mid lebbisan, qallafsanaanta dusha sare ka dib marka la shiido ganaaxa waa in ay u dhowdahay qallafsanaanta dusha sare ka dib marka chromium dahaadhid iyo dhalaalid.Haddii qallafsanaanta dusha sare ee usha piston loo baahan yahay inay ahaato mid sare, sida Ra <0.2 μm, waa inay ahaataa mid si fiican loo jeexjeexay.Ku dar shiidid ama hab-socod si fiican u shiidi ka dib.