HLQ/STM SLIDE Miiska WASAXA HAWADA ALUUMIUMKA

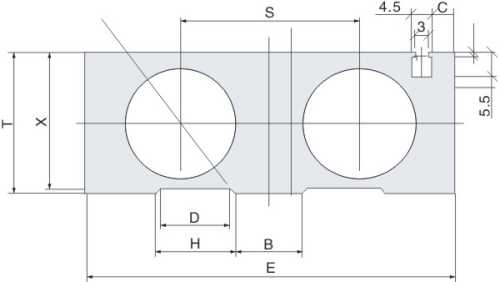

Taxanaha STM

| NO | d | E | X | T | D | H | B | C | S |

| 1 | Φ10 | 44 | 16 | 17 | 8 | 10 | 8 | 1.5 | 18 |

| 2 | Φ16 | 59 | 22 | 23 | 11 | 13 | 14 | 1.5 | 30 |

| 3 | Φ20 | 68 | 25 | 26 | 13 | 16 | 17 | 1.5 | 35 |

| 4 | Φ25 | 82 | 31 | 32 | 16 | 18 | 15 | 5 | 40 |

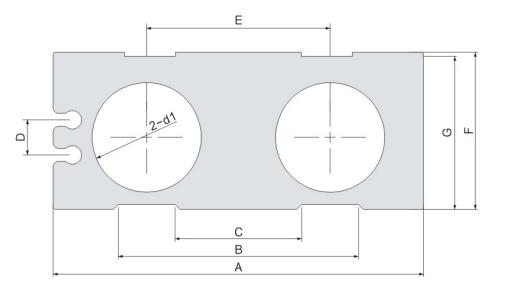

HLQ (φ6-25) Taxane Slide Miiska Dhuumaha

| NO | 2-d1 | A | B | C | D | E | F | G |

| 1 | φ6 | 30.6 | 17.4 | - | 5.2 | 12 | 11.5 | 10.9 |

| 2 | φ8 | 40.6 | 24 | - | 5.4 | 17 | 14.1 | 13.5 |

| 3 | φ12 | 50.8 | 28 | 12 | 6 | 20 | 19.4 | 18.5 |

| 4 | φ16 | 60.8 | 38.6 | 15.4 | 6 | 24 | 24.3 | 23.3 |

| 5 | φ20 | 70.8 | 44 | 20 | 6 | 32 | 29.6 | 28.8 |

| 6 | φ25 | 84.8 | 55 | 29 | 8 | 42 | 35.8 | 34.9 |

Qalabka Aluminium Alloy Profile Aluminium tube dhululubo pneumatic ah: aluminium alloy 6063 T5

Dhererka caadiga ah waa 2000mm, haddii aad u baahan tahay dherer kale, fadlan si xor ah noogu soo wargeli.

Dusha Anodized: tube gudaha-15 ± 5μm dibadda tube-10 ± 5μm

Heshiisyada naqshadeynta FESTO, SMC, Airtac, Chelic iwm.

Sida waafaqsan heerka ISO 6430 ISO6431 VDMA 24562 ISO15552 iwm.

Waxaa loo isticmaalaa dhululubada caadiga ah, dhululubo is haysta, dhululubo mini, Dual Rod cylinder, Slide cylinder, Slide Table cylinder, Gripper iwm. Sidoo kale qaar ka mid ah dhululubada gaarka ah.

Halabuurka Kiimikada:

| Halabuurka Kiimikada | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Faahfaahin:

| Xoogagga kacsanaanta (N/mm2) | Xoogga Wax-soosaarka (N/mm2) | Awoodda (%) | Adagnaanta Dusha | Saxnaanta Dhexroorka Gudaha | Qalafsanaanta Gudaha | Toosanaan | Qaladka Dhumucda |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Dulqaadka Aluminium Alloy Tube:

| DULMIGA TUBE ALUMINIUM | ||||||

| Cabbirka Bore | Dulqaad | |||||

| mm | H9 (mm) | H10 (mm) | H11 (mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: Waa maxay noocyada miiska silbashada ee dhululubo pneumatic ah ayaa jira?

A: Moodeelku waxa uu leeyahay MXS iyo STM dhululubada pneumatic

Q2: Waa maxay miiska silida ee dhululubada pneumatic?

J: Slinder miis Sylinder pneumatic: Miiska silbashada oof-wareenka waa hannaan wadista toosan oo si weyn looga isticmaalo warshadaha otomaatiga ah.Waxaa si weyn loogu isticmaalaa goobta qalabka mashiinka, qalabka otomaatiga ah iyo robots.Guud ahaan waxa ay wadaa hawo cufan, dhaq-dhaqaaqa toosan ee slider-kana waxa lagu xaqiiqsadaa gudbinta isku-dhafka ah ee kubbadaha saxda ah iyo biraha siligga ah ee toosan.

Q3: Ma jiraan faa'iidooyin?

A:

1 Isku-dhafka is haysta ee miiska sibidhka ee Sylinder Pneumatic Sylinder iyo Sylinder Pneumatic;

2. Sylinder-ka saxda ah ee Pneumatic wuxuu ku habboon yahay miisaska silbashada pneumatic ee isu-ururinta saxda ah;

3. Qalafsanaan sare / saxsanaan sare, qalab istaroog oo la hagaajin karo oo ikhtiyaari ah (0-5mm);

4. Miiska silbashada ee Sylinder Pneumatic wuxuu qaataa hagaha kubbadda iskutallaabta, kaas oo leh khilaaf hooseeya oo ogaan kara dhaqdhaqaaq siman oo aan dabacsanaan lahayn;

5. Isku-dhafka Sylinder Pneumatic iyo miiska shaqada waxay yaraynaysaa cabbirka guud;

6. Qaab-dhismeedka Silinder-Pneumatic Double-Pneumatic ayaa la qaatay si loo helo laba jeer xoogga wax soo saarka;

7. Nooca giraanta magnetic-ka ee la dhisay, furaha birta ah ayaa lagu rakibi karaa.

8. Syladaha pneumatic ee miiska sambabada pneumatic pneumatic Sylinder waxaa guud ahaan loo isticmaalaa gaadiidka iyo gaadiidka qalabka saxda ah, saxnadu waa mid aad u sareysa.

Q4: Waa maxay cabbirka MXS?

A: Cabbirku wuxuu leeyahay Dia 6mm, Dia 8mm, Dia12mm, Dia16mm, Dia20mm